A sales agreement with sister company Nash Pumps has just been announced

With an impressive list of mill references in Europe and Asia, Runtech is set to make its mark in the western hemisphere.

With the recent announcement of a cooperative sales agreement with sister company Nash Pumps, it feels it is well-positioned to do so.

Founded in 1997, Finnish-based Runtech specializes in vacuum systems/turbo blowers, doctoring and tail threading. In the past 25 years, it has grown considerably. In 2008, it acquired Ecopump; in 2011, Selotech; and finally, the EV Group in 2018. It has two manufacturing facilities, both in Finland.

In 2017, it established itself in the US with the formation of Runtech Systems Inc. This was followed the next year by Gardner Denver, part of Ingersoll Rand, acquiring the company.

With a number of references in North America, the company is looking to fortify its position here. The agreement with Nash Pumps should play a key role in achieving the goal.

Anna-Riina Ahonen, Marketing Manager, Runtech SystemsThe companies will combine their sales efforts in North America and Europe. With both liquid ring and dry blower technology, comprehensive paper machine dewatering and vacuum system options are available. Hybrid systems using both liquid ring and blower technologies are a possibility. Anna-Riina Ahonen, marketing manager, says, “With this unique portfolio we can always find a perfect fit for our customer’s demands, needs and budget.”

Anna-Riina Ahonen, Marketing Manager, Runtech SystemsThe companies will combine their sales efforts in North America and Europe. With both liquid ring and dry blower technology, comprehensive paper machine dewatering and vacuum system options are available. Hybrid systems using both liquid ring and blower technologies are a possibility. Anna-Riina Ahonen, marketing manager, says, “With this unique portfolio we can always find a perfect fit for our customer’s demands, needs and budget.”

Runtech is really looking at the retrofit market in North America. “A lot of mills are using liquid ring pumps. One of the goals is to modernize existing vacuum systems. There are a lot of retrofits that need to be done.”

Although Runtech is happy to work with greenfield mills, Ahonen points out that, “Rebuilds are our strength because the units are small and easy to install. We can fit them anywhere with minimal downtime.”

She adds that the company has now installed more than 850 turbo blowers worldwide. China has been the best market with many greenfield mills opting for blower technology. In 2021, over 50 units were installed in the country.

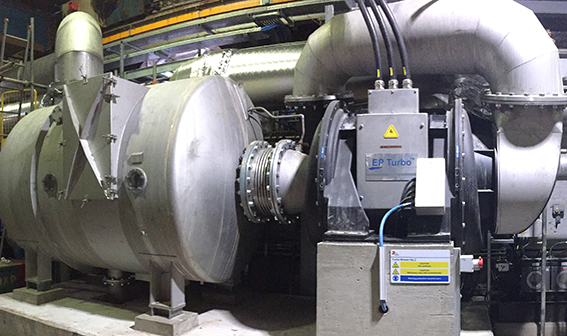

Turbo Blower EP600 installed at DS Smith Kemsley, UK

Turbo Blower EP600 installed at DS Smith Kemsley, UK

In Europe, all the major new board machines have installed Runtech blowers. Europe should also be a strong market for retrofits in the coming years, Ahonen notes. Runtech’s turbo blowers can be used for all paper grades, from tissue to board.

What advantages does turbo blower technology offer? The most important are include energy savings and reduced water consumption. “Striving to become more carbon neutral, our blowers stand out.” Mills that recycle their water via cooling towers struggle with the care of the tower and the increased maintenance of their pumps, so a dry system can be an attractive alternative.

An additional advantage that the Runtech EP Turbo Blowers provide is that they are the first available with variable speed and capacity. They offer a completely water-free vacuum system with significant heat recovery potential (1.5-16 m3/sec or 3,000 to 34,000 cfm), no matter the paper grade.

Ahonen stressed that Runtech’s offerings extend far beyond blowers and pumps such as the aforementioned doctoring and tail threading as well as save-alls and pocket ventilation.

Paper machines audits are another part of the business. “One of our specialties is optimization,” Ahonen explains. “More is not always better. You need to know where to measure to know how much vacuum is needed and how much water is being removed. Our turbo blowers are adjustable so they use only the vacuum needed. This ensures no extra energy is used.”

EcoFlow dewatering measurement installation

EcoFlow dewatering measurement installation

A Runtech white paper notes that vacuum is on of the top three energy consumers in a mill. By using vacuum only in the most critical positions, a mill can benefit from a more efficient nip dewatering strategy and save energy. Measuring water flow online accurately helps optimize vacuum levels so as not to overdo them. Runtech’s EcoFlow was developed to provide a reliable and accurate online dewatering measurement system for water that has a lot of air.

With thousands of vacuum system audits and dewatering studies done at mills worldwide, Runtech can benchmark the effectiveness of existing vacuum systems, dewatering equipment, suction elements, fabrics and felts.

The combined expertise in this equipment allows the company to provide a “holistic” view for improved paper machine dewatering and energy efficiency.

Finding your way in a new market can take time, but coupled with a global pandemic can greatly complicate the effort. However, Ahonen is confident. “Customer feedback in North America has been good. COVID has affected us,” she admits. “There has been a lot of uncertainty and customers have postponed investment decisions. But, people have become used to working in this environment with virtual meetings so business is as back to normal as it can be. Overall, customers have been very understanding.”

RunEco vacuum system at Progroup PM3 in Sandersdorf-Brehna, Germany

RunEco vacuum system at Progroup PM3 in Sandersdorf-Brehna, Germany

She cites a recent startup of its first blower in New Zealand, a country with very strict COVID regulations. “The customer was very happy and the way we were able to proceed with the installation.”

With its expertise and large reference base, Ahonen says Runtech wants to be a “one-stop shop” for clients. “We can cover the whole paper machine and solve many papermaking issues for clients. We can do a wide range of audits.”

Ahonen says that Runtech has assembled a good team in North America capable of audits as well as selling and servicing equipment. “Nash service people have been trained to service Runtech blowers in North America while Runtech can service Nash pumps in Europe.”

In conclusion, Ahonen says, “We’re still trying to establish ourselves in North America, but our cooperation with Nash will help. We have a good solution to help save money and we believe North American mills will see this.”

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Graeme Rodden has covered the pulp and paper industry for more than 40 years, including serving as editor of several well-known paper industry magazines.

Graeme Rodden has covered the pulp and paper industry for more than 40 years, including serving as editor of several well-known paper industry magazines.