A supply shortage of good and white conventional recycled papers can be felt in Europe and in many other places around the world. For different reasons concerning market evolution, this situation is expected to stay the same or even worsen in times to come. This has pushed the market to seek out alternative fibers.

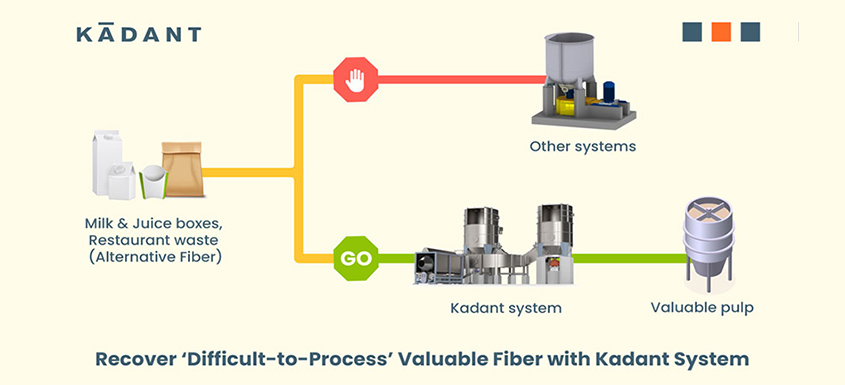

The alternative fibers today consist of what may be considered non-recyclable or difficult to manage but are often identified to contain fibers of superior quality. Due to the difficulty of recycling them, not many system providers can process these fibers, and they are more available in the market. Hence, there is a need to develop new pulping processes as well as a new recycling line to fully process these fibers.

Some examples of alternative fibers could be Used-Beverage-Cartons (UBC), Polycups, and complex fiber-based products with strength and features similar to treated papers with good wet strength.

Contrastingly, the second category of alternative fibers that are more easily accessible in the present situation is the annual plant fibers which include straw, bagasse, and even clothes textile fibers. Interestingly, the market for these alternative fibers is predicted to grow and witness no shortage in the next 10 to 30 years.

The Need for Alternative Fibers

The boom we are seeing in the alternative fibers segment today is startling, and there are a couple of reasons that explain this deviation:

- Shortage of good raw materials and white raw materials: Typically, the containerboard market segment has a recycling rate of 94%; as it undergoes subsequent recycling, it grows weaker, thereby creating the need for new alternative fibers that can be used to re-strengthen and restore the board's properties. For white grade, getting a suitable raw material is a growing challenge that can only be compensated by treating OCC to produce tissues. The need for such fiber is prevalent across all pulp mills, especially in the EU.

- The arrival of the new complex, recyclable packaging materials to reduce and substitute plastic usage: Some estimates suggest that the demand for these alternative packaging materials is to grow up to 1.5 million tons across the EU while methodologies for their collection and sorting is already underway.

Kadant Addressing the Alternative Fiber Market

Understanding the customers' specific needs for their respective mills is imperative to address and grow closer to them. We, at Kadant, help our customers by collecting insights on the different fibers and the strategy to treat them, while also trying to pinpoint their needs, for example:

- If the customer wants to reduce the cost of raw materials,

- or, have strength development needs

- or, have identified special grades that suit the needs but are beyond their current capability to recover fiber from it

Our Offerings and Support

It's important to support the customers from the beginning of their alternative fibers journey, and Kadant does it in many ways:

- Our Technology and Innovation Center at Kadant Lamort, France allows our customers to test their raw materials in the lab settings and we offer a consolidated report at the end.

- Heli-Drum pulping system - Specially designed latest generation pulping system for the possible high-consistency alternative fibers. It promises low horsepower, low operational cost, superior ink dispersion, low sensitivity to poor contamination levels, and high capacity.

- Dedicated compact line to treat alternative fiber at an appealing package.

- Flexible recycling line that not only copes with conventional grades but is also versatile enough to handle alternative fiber challenges.

Written by:

Utkarsh Agarwal

Global Marketing Specialist, Kadant India

Alain Lascar

Technology & Innovations Director, Kadant Lamort

Source: Kadant