Ittihad Paper Mill (IPM) is the first printing and writing paper mill in the GCC (Gulf Cooperation Council) and the largest in the Middle East North Africa region. With ABB Ability™ Manufacturing Execution System, the mill was able to optimize production management while meeting their end customer expectations on delivery and quality.

The situation

- Strategic industrial investment to cater to the growing regional demand for printing and writing paper

- Greenfield site that required a system ready at start-up for production planning and quality management, as well as order-to-delivery

The solution

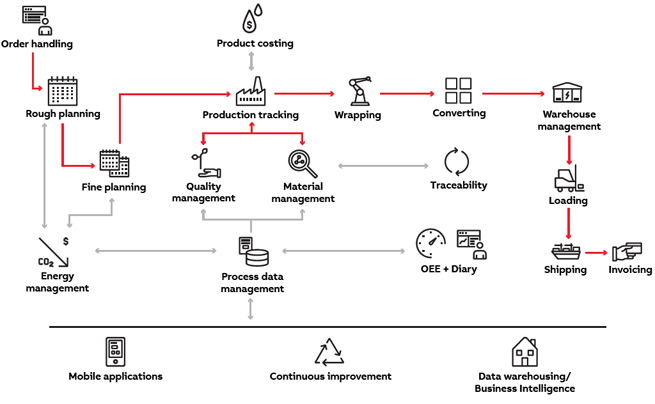

- Implemented ABB MES for pulp and paper

- Initially also included Order Management so the mill could manage orders and deliveries until the order

management function was migrated to SAP - L&W Autoline

Greenfield site with an eye on production management

The IPM mill produces high-quality uncoated wood-free paper; according to IPM, their products are strictly in compliance with global environmental standards and its pulp is sourced only from certified sustainable forests. With a capacity of 320,000 tons annually (or the equivalent of 65 billion A4 sheets per year), the mill serves the needs of both regional and global markets.

IPM was established near Abu Dhabi as a strategic industrial investment to cater to the growing regional demand for printing and writing paper, which had previously relied on imports. As a greenfield site in 2017, the mill required a system ready for start-up that would help address production planning and quality management while also handling the full order-to-delivery process to meet the needs of their global customer base.

Successful start-up

IPM chose ABB Ability™ Manufacturing Execution System (MES) for pulp and paper. While a full integration to SAP was planned, it was not ready at start-up. The initial ABB MES implementation included the Order Management module so the mill could manage orders and deliveries until the order management function was migrated to SAP.

“In general, it was a smooth process. At the beginning, we had difficulties to customize the machine and process,” said Saad Qureshi, System Administrator. “But once the paper machine started –with real orders and real cases, not just what-if scenarios—this helped get the process smoother and the operation easier for us. Especially with the training (from ABB).”

Because the mill was the first pulp and paper site in the area, a lot of employees were new to the paper making process and systems – including MES.

Once the site personnel were able to manage daily operations in the new production environment, ABB provided additional training to efficiently use extensive algorithms and functionality to optimize production through the paper machine and beyond, through to the fleet of sheeters.

ABB’s MES helps to plan production over the winders and sheeters taking the full width of the paper web into use. According to Khalil, this functionality helps minimize waste in every production step, saving money for the site.

High focus on quality

As the mill got up to full speed and focused on growing their customer base, they made sure to highlight their investment in quality to prospects and customers visiting the mill.

“Whatever customer was visiting our mill during start up, we were making sure to give a tour of both MES and Autoline and their contribution to quality,” said Qureshi. “Autoline is connected directly, so we are able to get readings and make changes online. For example, auto controlling for basis weight or moisture profiles.”

ABB’s MES connects to the paper machine’s automation, quality control and web inspection systems to provide online moisture, grammage and caliper profiles in the form of color maps. Samples of each jumbo reel are sent to ABB L&W Autoline, which is also directly connected to the MES, where additional quality measurements are performed and recorded as quality certification records for each order produced.

The high automation level of the mill coupled with the full end-to-end production and quality management provided by MES gave IPM's end customers peace of mind to place important first orders even before the start up.

End-to-end traceability

The system enables the mill to trace a product from the headbox through the final customer delivery. This order-to-delivery visibility has helped with traceability and managing any customer issues.

“It has the capability to trace any movement, whether from warehouse or to machine floor,” said Qureshi. “It connects all the departments together. Logistics. Sales. Production. It’s very powerful.”

One of the key advantages of MES is having all operations managed behind one user interface, creating full transparency and removing operational silos.

Improved productivity with less hours worked

One of the things that stood out was how operations can be optimized to provide support where it was most needed because the MES could automate many manual tasks.

“We are getting more accurate data with MES with less effort,” said Qureshi. “That’s why we are planning to expand to our sister site. They have SAP, but on the production level, we see that it’s better to have MES to control and monitor the process.”

Plus, when an order is entered into the MES, the system will search for the earliest production block that is available, even recommending the shipment dates. “The ability of the MES to connect and manage the flow of the work, I’d say that is the most important thing,” said Khalil. “We can do adjustments or change shipping dates – all key factors for success while also better managing expectations with our end customers.”

And those customer expectations are met, with the MES helping IPM achieve a high delivery accuracy with only two planners. According to Khalil: “To achieve that accuracy outside the system, it would depend on the planner. But I would need seven to get the same accuracy.”

Qureshi added: “With the system, you gain efficiency and accuracy. There’s no human error so what dates you get, they are accurate.”

Conclusion and future plans

As the mill considers centralizing their planning department for future mill expansion, they already see the efficiency benefits such a scenario could bring in pulp and paper mills. “I would recommend this for future expansion. So yes of course to others (mills),” concluded Qureshi.

Source: ABB